TLDR - It feels too good to be true but things are going great

Hi all ![]()

Greetings from Minneapolis where we are in the midst of a big blizzard! ![]() I figured it’s about time to share an update on Ribbons’ spring production run and all the things we’ve been working on at Kinotone. Let’s get into it!

I figured it’s about time to share an update on Ribbons’ spring production run and all the things we’ve been working on at Kinotone. Let’s get into it!

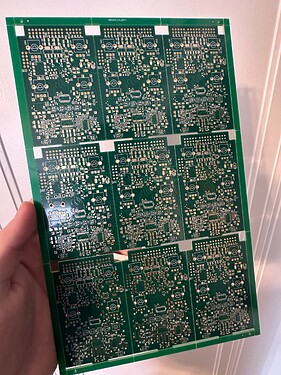

PCB assembly is in full swing, enclosures are getting delivered next week, and I finally feel like I’m able to breathe a little while we wait on other vendors. In about 2 weeks we’ll have all of the electronics in-house, at which point we’ll hand solder a few through-hole components to each board and then we can move on to the next steps - final assembly, testing, and packaging. We are right on track to be able to start shipping units in April.

I know there can be a lot of uncertainty when you pre-order a new product from a small startup. You hope that the business will put together a good schedule and deliver on what they promise, but it seems like it’s a classic trope for Kickstarters to get delayed by months or longer. We almost found ourselves in this exact situation right as the pre-order was opening but we rolled up our sleeves and overcame some huge challenges that have led to everything going surprisingly well. It’s kind of a long story but I think it’s important to share. OK… here we go:

When we announced our pre-order we did so based on the news that our DSP chip (STM32H7) would be shipping in March 2023. Until then it was backordered “52+ weeks” which made it impossible to make any plans. The H7 chip is like gold right now. Check this lead time from an authorized distributor. It’s used in high-end automotive displays, medical devices, and many other music products (Fender, Mutable, CBA, Qu-Bit, 2HP, Isla, etc.) The supply chain is extremely constrained by the pandemic “chip shortage” that I’m sure you have all heard about.

At the end of last year we started publicly sharing that we would be opening a pre-order in January ’23. We just had to source a few final parts before announcing an official date. Everything was going great… then one morning we’re at a coffee shop and I receive an email that our chip delivery is delayed until June ’23. This of course blows everything up. We consider canceling the pre-order altogether, which feels awful and kind of like Kinotone folding before it’s even gotten started. We considered the possibility of just opening the pre-order as-is and asking people to pay for something now and wait 6 months to receive it, which also feels awful. So I put on my engineer hat and tried to figure out a solution.

I remembered that Andrew Ikenberry from Electro-Smith reached out to us way back in September, basically introducing himself and offering to help with sourcing the H7 chip if we ever needed it. They use it on their Daisy Seed platform and their supply chain is more stable due to their economy of scale. I didn’t think much of it at the time because we didn’t need any help, and the H7 chip they use is slightly different than ours - I just didn’t think it would work.

Since we didn’t have chips coming in anytime soon we decided to meet with Andrew and discuss some options. Ribbons has two 6-layer PCBs: the main control board and a smaller microprocessor board. The microprocessor board is the brain and memory of the device and includes the DSP chip. The possibility was floated of using the Electro-Smith Daisy Seed for that board, which was appealing because in that scenario, if their H7 chip worked with Ribbons, I’d just need to create an adapter board instead of designing a brand new 6 layer PCB from scratch. Designing a 6-layer PCBs is a pretty challenging task and even though I’ve done it many times it poses a risk that something could go wrong.

They overnighted me a sample of the Daisy Seed and I spent about a week and a half putting in some crazy hours working through some really tough questions. At first I was skeptical and didn’t think that it would work. It has a tiny amount of internal FLASH and lots of external FLASH, which is basically the opposite of our first chip - I thought the external flash would be too slow and create a bottleneck. Luckily I’m very familiar with the H7 as I’ve spent the last 3 years developing my own hardware and DSP libraries for it, and I had a hunch that if I made some specific changes I could pull it off. I re-wrote the audio bootloader to store the application in external FLASH, updated the presets to be stored in external FLASH, re-wrote almost all the drivers because the pinouts were different, updated the SRAM drivers for a different SRAM chip, re-worked the linker script, and more.

And in the end… it worked fantastic! I had enough confidence in the Daisy Seed that I felt good about opening orders at the end of January - more or less when we planned to. I now have 2 separate code bases, one for Ribbons that uses our original H7 chip, and another for the pre-order units. Andrew and his business partner Stephen Hensley were extremely helpful and it was nice to have another engineer be like “yep! you’re on the right track, this will totally work.”

Anyway, that’s the big story. Original Ribbons and “new” Ribbons will be indistinguishable for the end user (unless you pop the back off and look inside to change your TRS MIDI jumpers, then it will just look slightly different). I’ve crushed all the bugs that I’m aware of and have a few local beta testers spending time with it over the next couple weeks.

Some other stuff we're working on:

My dear friend Pat has been hand building and soldering a thousand footswitches. You can order them pre-soldered from Taiwan but they take ~40 weeks to arrive, so that wasn’t really an option. Pat also babysits Snippy the insulation cutter. Snippy overheats and needs to take a break every 10 or so minutes. We really appreciate Pat and are grateful for his help.

My partner Hannah (who has become a huge part of Kinotone over the last few months ![]() ) helps me keep up with customer service and all kinds of random but very important things day to day. She is working on a printed user manual that all of the new units will come with. Her sister is an amazing designer and the two of them are also partnering up on a new box design. Brace yourselves ya’ll… the packaging is gonna be beautiful. And we have stickers! Of course we bought extra of both of these things for current Ribbons users so that nobody gets FOMO about the new stuff.

) helps me keep up with customer service and all kinds of random but very important things day to day. She is working on a printed user manual that all of the new units will come with. Her sister is an amazing designer and the two of them are also partnering up on a new box design. Brace yourselves ya’ll… the packaging is gonna be beautiful. And we have stickers! Of course we bought extra of both of these things for current Ribbons users so that nobody gets FOMO about the new stuff.

I’ve also been working on some 3D printed fixtures and writing scripts to speed up assembly and make end-of-line testing more efficient. And last but not least I’m writing firmware for the final features of Ribbons. Kind of its own topic but …

New features in the works:

- Crushed Cassette Touch Mode - Sample rate reduction and bit crushing using u-law companding. There are some good clips of this on our Instagram.

- Disintegration Loop Touch Mode. This is the last one (IMO there is room for 6 total touch modes using the current UI). Lots of people wanted loop decay but I didn’t want to add that to the looper mode, so doing it as its own touch mode made more sense. I’m going write a separate post about this shortly and open it up for feedback if anyone has any.

- Tape Saturation. I’m doing it ya’ll. I finally got it to sound pretty dang incredible (I think so at least) with aliasing reduction which had been my main concern. I recently had an opportunity to try out another lo-fi pedal that has tape saturation and I just wasn’t in-love with it… so that, along with some code optimizations that freed up another 5% of the CPU, kinda pushed me over the edge to give it a shot. The saturation feature will be available by sending Ribbons a MIDI CC message that turns the Compression knob into a Saturation knob. It will be persistent between power cycles, will be integrated into our M4L device, and you can switch between Compression and Saturation whenever you want.

All new features will be made available to current customers via firmware update, and pre-order units will ship with the latest installed.

So… that’s the Kinotone update for now. If you’re reading this, thanks for being on the forum! I’ll try to do more blog posts like this going forward.

I’ll leave you with some pictures of production stuff over the last few weeks:

The current state of my desk:

Control / UI boards arrived last week:

Pots arrived from Thonk UK

Knobs arrived from Rogan

One thousand footswitches in-progress

New MCU boards using a stripped down version of the Daisy Seed

Writing firmware with a little help from my son (Sid)